Product description

| Product name | Plastic Bags |

| Shape | customized |

| Surface Handling | Gravure printing |

| Industrial Use | Shoes & clothing, APPAREL |

| Size | Customized Size |

| Plastic Type | LDPE |

| Color | Customized |

| Logo | Custom logo |

| Feature | Biodegradable, Eco-friendly, Heavy Duty |

| Packaging | Carton Packing |

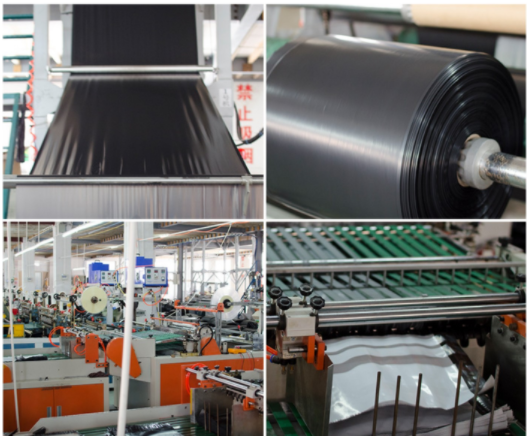

Plastic bag production process

1. Determine the specifications and printed documents:

Regarding the specifications of T-shirt bags, they are similar and non-uniform and can be customized according to customer requirements. Conventional specifications such as: 20*32cm, 25*40cm, 30*48cm, 35*55cm. The thickness of the single layer is not less than 0.025mm according to the standard of plastic limit order. The printed manuscript can be based on samples, or the customer can design it and give it to the manufacturer, or let the manufacturer do the design on his behalf.

2. Film blowing is performed according to the order quantity. Film blowing refers to a plastic processing technology in which plastic particles are heated and melted, extruded through an extruder, and then blown into a plastic film by a blower. The plastic t-shirt bag uses high-density polyethylene (HDPE, also known as low-pressure material) as the raw material.

3. The printing of plastic t-shirt bags is generally simple, the color is not complicated, and it is simple and concise.

4. The next step is sealing and cutting.

5. Sealing and cutting are to seal and hollow out the printed roll material, and it is also the last step in the forming of the vest bag.

6. Forming-packaging-shipping.